PHOTOS: ANDREW FREDRICKSON

PHOTOS: ANDREW FREDRICKSON

roper cable lubrication and maintenance is a much bigger part of a smooth ride than most people think. In this edition of Factory Tech Tip, learn how to keep your levers and throttle responsive, snappy, and smooth.

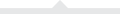

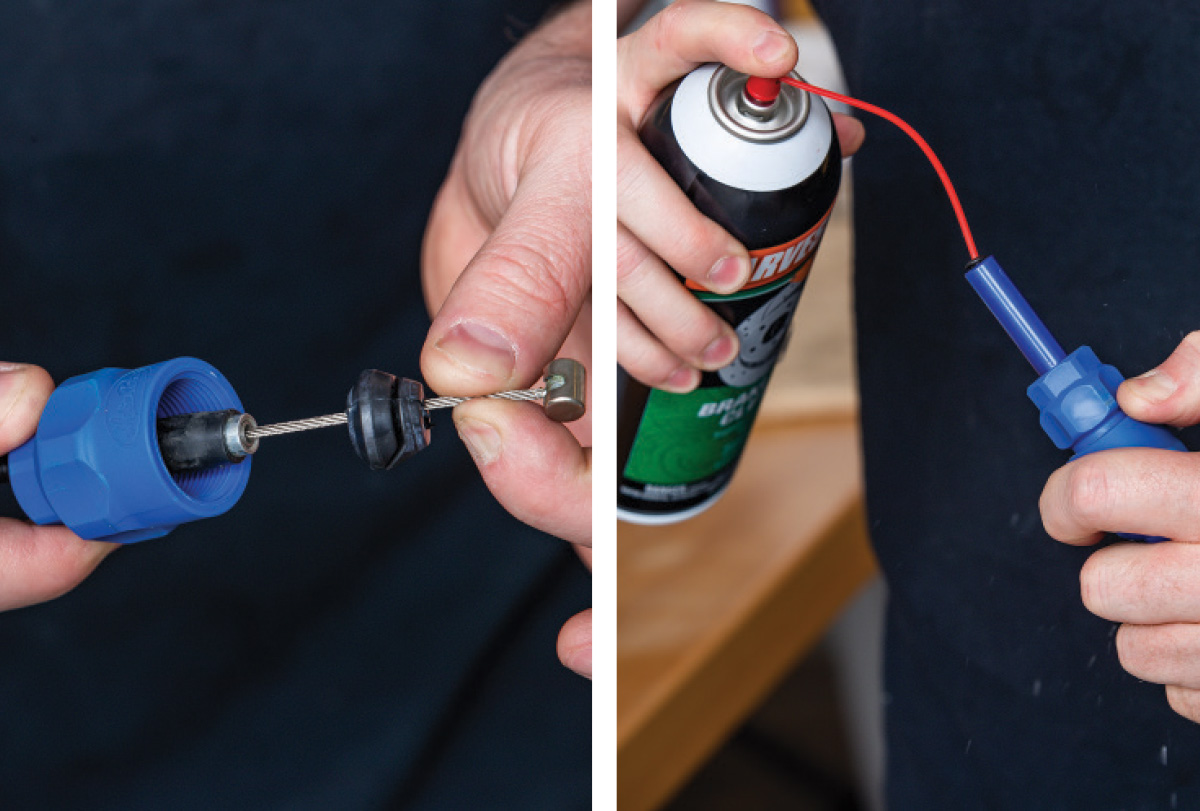

We started out with some contact cleaner. We used a Motion Pro cable cleaner and cable luber to work in the cleaner and lube. We started out with contact cleaner to remove all the debris, oils, and grease that was in the cable to begin with.

We started out with some contact cleaner. We used a Motion Pro cable cleaner and cable luber to work in the cleaner and lube. We started out with contact cleaner to remove all the debris, oils, and grease that was in the cable to begin with.

We then removed the cable luber and aired out the cable, forcing air down through it. That helps dry out the cable and remove the contact cleaner.

We then removed the cable luber and aired out the cable, forcing air down through it. That helps dry out the cable and remove the contact cleaner.

Next we reinstalled the cable luber, in this case using a significant amount of WD-40 to lube the cable. (You can also use Tri-Flow or another brand of cable lubes.) We then forced air through there to remove the excess WD-40, also ensuring that the lube went all the way through the cable.

Next we reinstalled the cable luber, in this case using a significant amount of WD-40 to lube the cable. (You can also use Tri-Flow or another brand of cable lubes.) We then forced air through there to remove the excess WD-40, also ensuring that the lube went all the way through the cable.

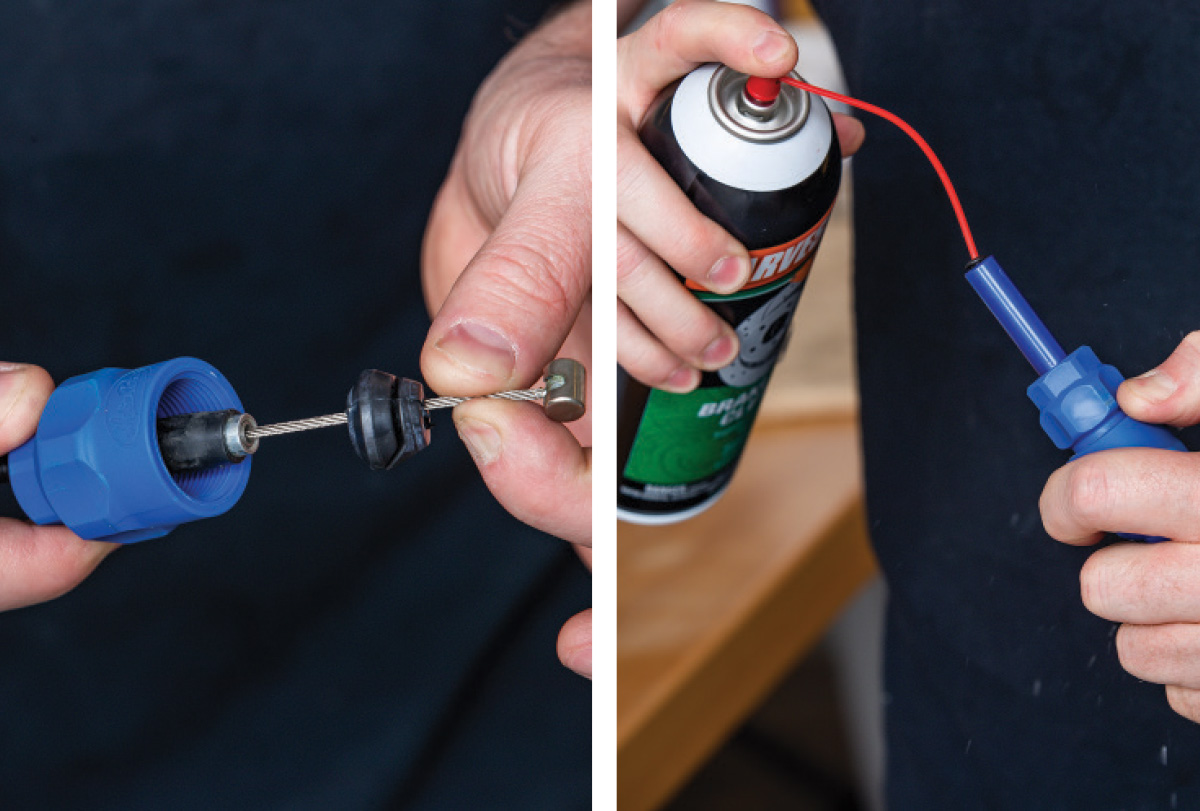

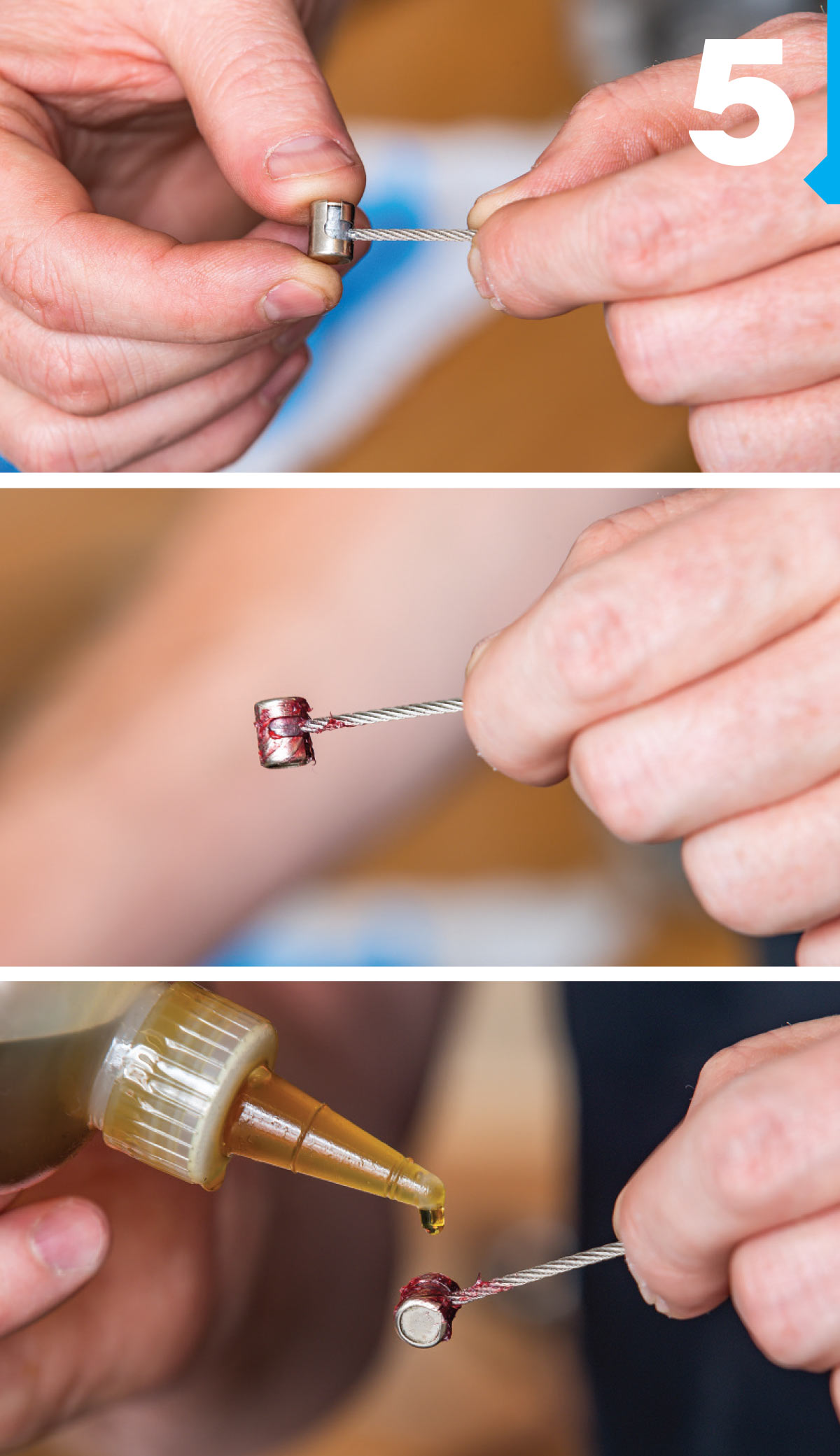

Next we greased the ends of the cable and moved them in and out of the housing, greasing the unseen area.

Next we greased the ends of the cable and moved them in and out of the housing, greasing the unseen area.

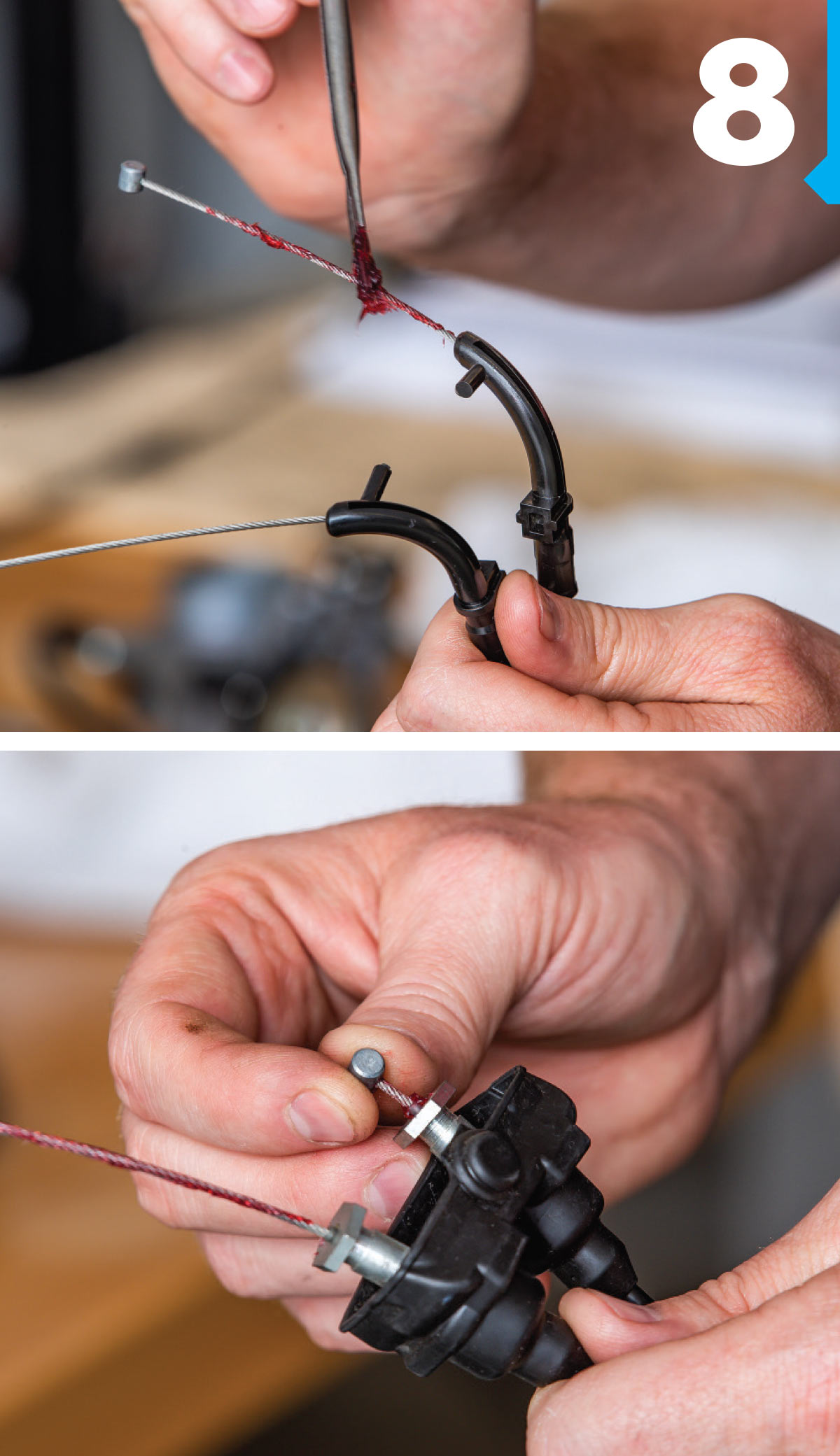

Then we greased the very end of the cable, which is like a ball. There’s a little sleeve on some of the clutch—I like to put that sleeve with the opening facing down and work that grease in behind that sleeve. I also like to put a drop of oil on that sleeve, and again work it in behind it to allow that little sleeve to pivot.

Then we greased the very end of the cable, which is like a ball. There’s a little sleeve on some of the clutch—I like to put that sleeve with the opening facing down and work that grease in behind that sleeve. I also like to put a drop of oil on that sleeve, and again work it in behind it to allow that little sleeve to pivot.

Now we moved down to the clutch arm itself. I like to grease the end of it where the cable rides—pretty simple, just a light layer of grease. Then we moved over to the throttle cables.

Now we moved down to the clutch arm itself. I like to grease the end of it where the cable rides—pretty simple, just a light layer of grease. Then we moved over to the throttle cables.

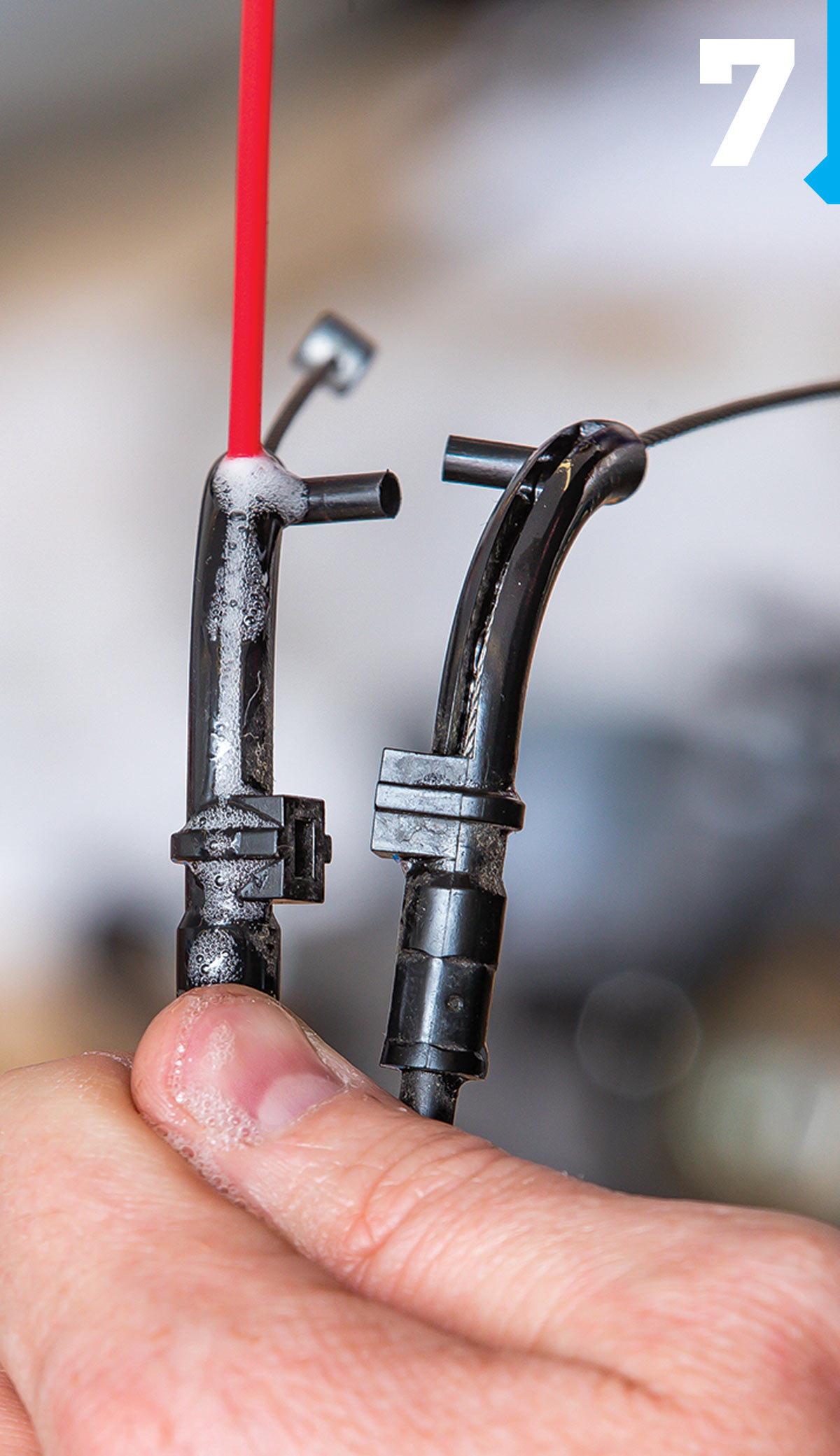

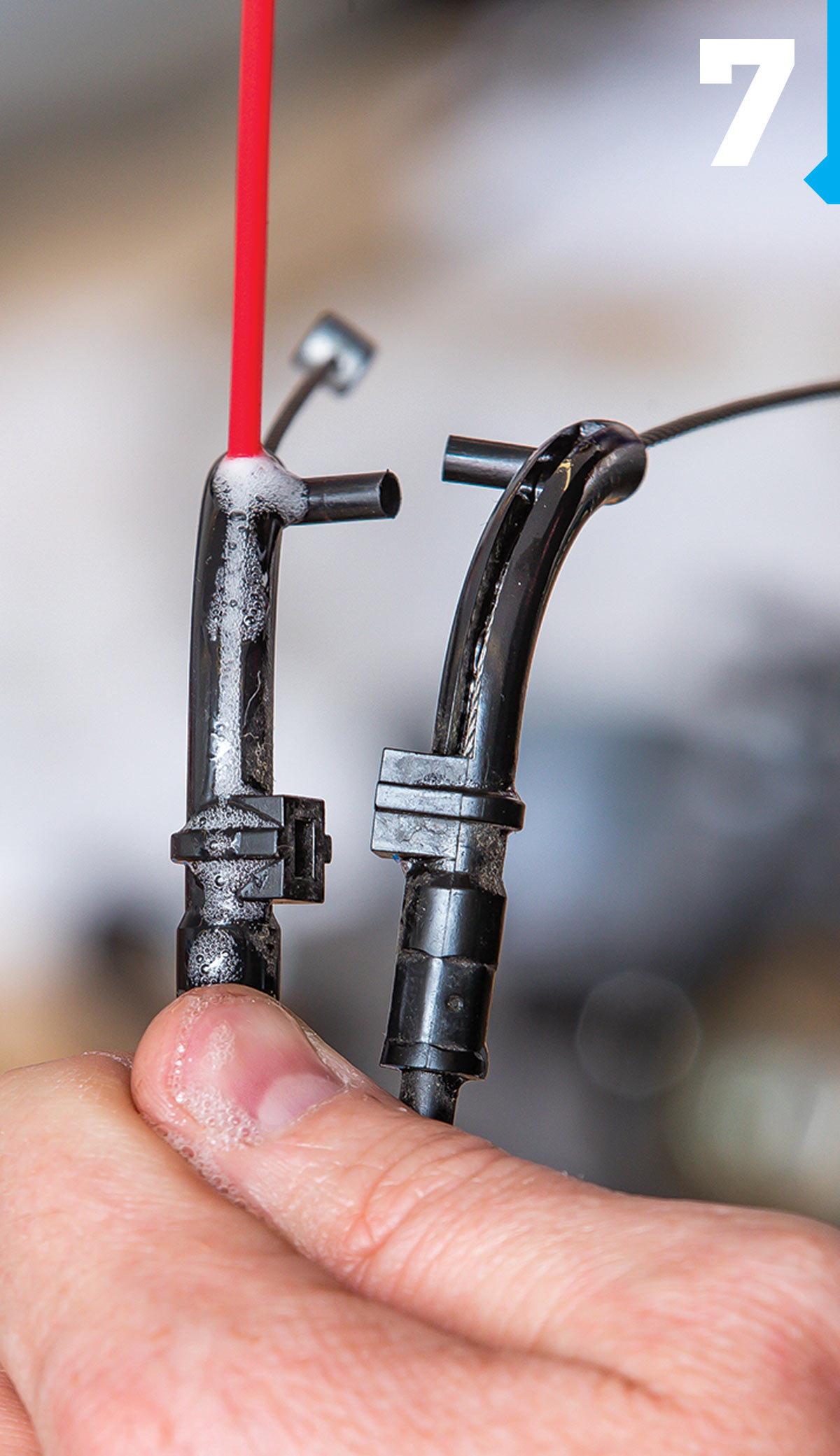

Pretty much the same principle: clean out the old debris from the cable using contact cleaner, then air it out. Then we used WD-40 down the actual cable guides in the throttle tube (the black cable guide, where it actually goes into the housing). We sprayed WD-40 in those grooves and then worked it down through the cable.

Pretty much the same principle: clean out the old debris from the cable using contact cleaner, then air it out. Then we used WD-40 down the actual cable guides in the throttle tube (the black cable guide, where it actually goes into the housing). We sprayed WD-40 in those grooves and then worked it down through the cable.

I like to put a little grease on the guide itself where the cable runs in the black guide and work that in and out so it’s nice and even. This will make a difference on how the cable feels when twisting the throttle once everything is assembled again.

I like to put a little grease on the guide itself where the cable runs in the black guide and work that in and out so it’s nice and even. This will make a difference on how the cable feels when twisting the throttle once everything is assembled again.

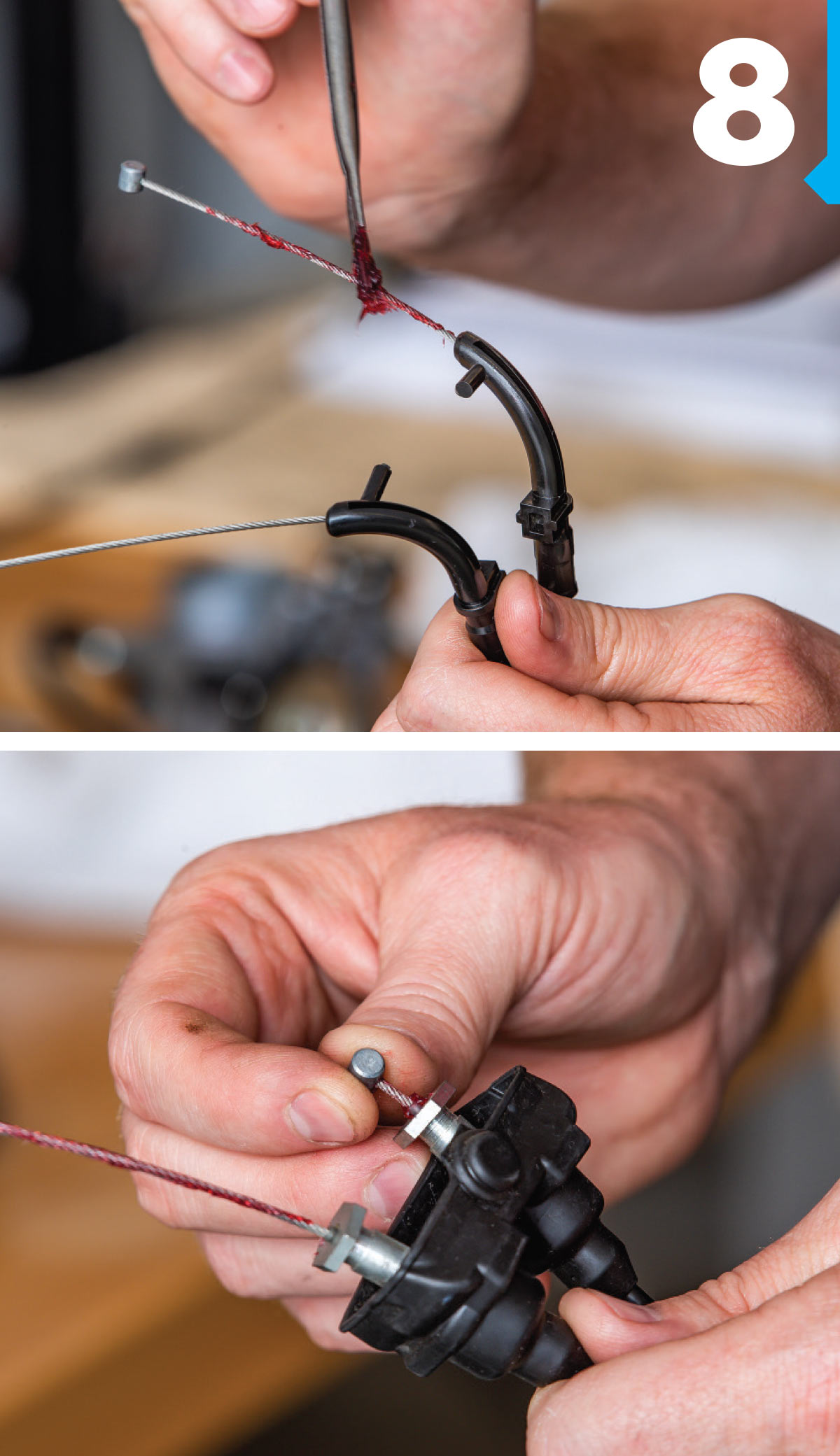

Then we moved on down to the throttle housing going to the throttle body itself. We greased the grooves in the wheel and where the cable runs in the wheel itself. I like to keep that greased so we don’t have the cable in direct contact with the steel wheel. Over time, those can wear out, or it can fray your throttle cable and it will eventually break. Then wipe off all excess so it doesn’t continue to track more and more dirt.

Then we moved on down to the throttle housing going to the throttle body itself. We greased the grooves in the wheel and where the cable runs in the wheel itself. I like to keep that greased so we don’t have the cable in direct contact with the steel wheel. Over time, those can wear out, or it can fray your throttle cable and it will eventually break. Then wipe off all excess so it doesn’t continue to track more and more dirt.

It’s a great idea to keep your cables cleaned and lubed. Your cables are going to last a lot longer, and it’s going to give you a real nice feel. Your throttle will be smooth and won’t stick—and if your throttle sticks, you could really get hurt. By keeping everything lubed and freed up and clean, it’s just going to give you a better throttle response and a better feel for what’s going on. You also may not get as tired if everything pulls and works a little more freely. ![]()